What is ‘Pick, Pack, Ship’? How does it make or break your e-Commerce business?

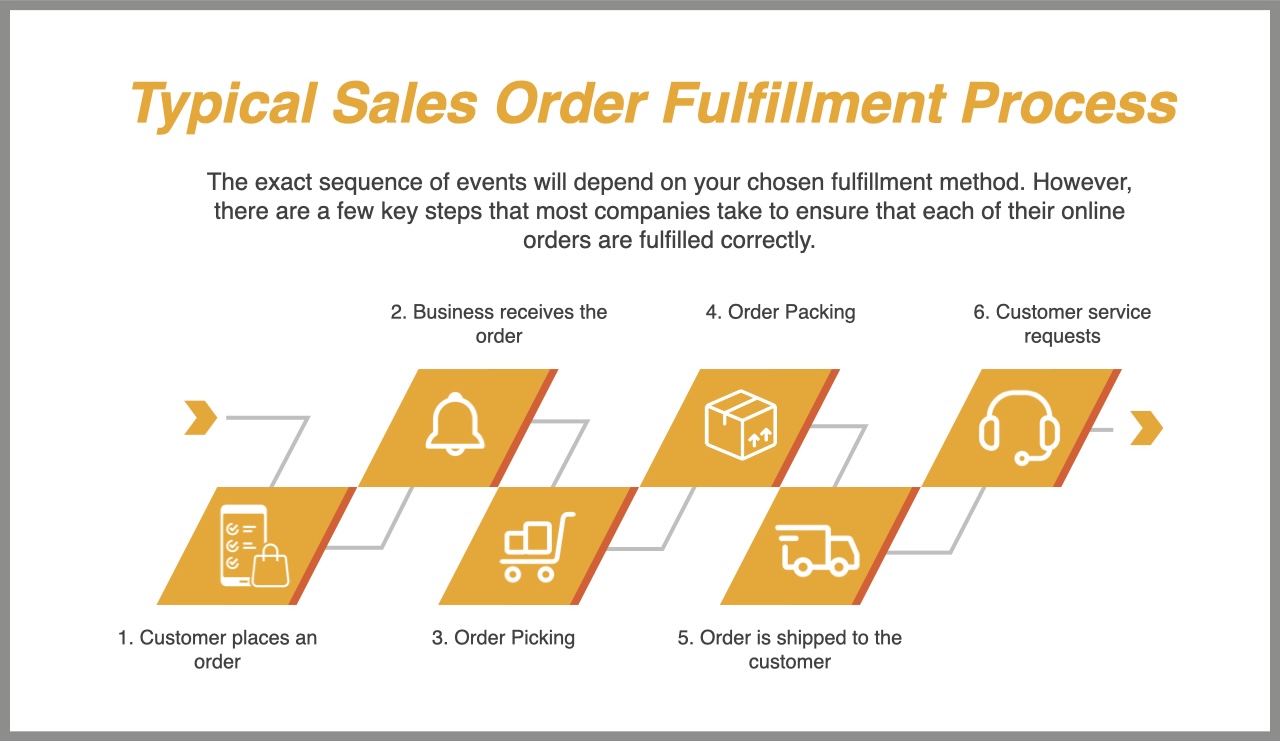

‘Pick, pack, ship’ is a common part of the physical process in order fulfillment, especially in e-commerce and retail. It refers to the sequential steps involved in preparing and sending out a customer’s order. When hundreds or even thousands of people order from your online store, sometimes it could be tricky to get products delivering to the customers in a timely manner. After all orders won’t magically get to where they need to be without proper preparation and procedure.

#1 A brief explanation of Pick, Pack, Ship

Before we start, here’s a brief explanation of each step:

Pick: This is the first step in the process. As its name explicitly implies, this step involves picking up the item(s) from the inventory that have been ordered by the customer. This could be done by workers or sometimes by automated systems identifying and physically retrieving the items from their storage locations/ shelfs.

Pack: After the items have been picked, they need to be packaged for shipping. In order to put together and protect the items during transit, the picked items are placed into appropriate containers (such as boxes or envelopes) and adding any necessary packaging materials like bubble wrap or packing peanuts.

For best practices, a delivery note (or shipping note) with detail information about the customer, your store, the list of goods and quantity being shipped must be provided in the shipped package.

Delivery note must be prepared and sent along with the shipment for a few purposes. Firstly workers can do a final check before sealing the box to ensure the package contain all the correct items. Besides, delivery note also serves as a key communication tool between the seller and the customer. It provides a clear record of the delivery. It is even more important if an order is partially fulfilled and split into different shipments. Customers can use it to verify the items received against what was originally ordered. It will save a lot of time in handling subsequent customer service calls.

Ship: Once the order is picked and packed, practically it is then shipped to the customer. This involves generating and affixing shipping labels to the packages. And arranging for a shipping carrier (e.g., SF Express, UPS, FedEx, USPS) to pick up and deliver the packages to the customer’s specified destination.

In-house order fulfillment

For many small businesses, the whole order fulfillment service is usually managed in-house. This means that every step in the process, from picking and packing the order to providing customer service, is entirely managed by their own employees.

#2 The importance of a good order fulfillment rate

The order fulfillment rate measures the percentage of customer orders that are successfully processed and delivered within the specified period of time. It is a critical metric that reflects the efficiency and effectiveness of a company’s warehouse and logistics operations. A high order fulfillment rate is indicative of a well-managed and responsive supply chain.

To calculate this number, compare the number of orders successfully fulfilled within a specific time period to the total number of orders received during that same period. The formula is as follows:

Order Fulfillment Rate (%) = (Total Number of Orders ÷ Number of Orders Fulfilled) × 100

For example, if a company received 500 orders in a month and successfully fulfilled 480 of them, the order fulfillment rate would be 96%. It indicates that the company successfully fulfilled 96% of the orders it received during that month.

Aging Unfulfilled Sales Orders

Although order fulfillment rate is a key performance indicator, it alone does not identify and reflect delays in order fulfillment. Unless your business is able to achieve 100% fulfillment rate all the time. Or else another area you need to pay attention to is the Aging (Unfulfilled) Sales Orders.

Aging Sales Orders tracks customer orders that have not been fulfilled within a specified time frame. By categorizing outstanding sales orders based on the length of time they have been open or unfulfilled, it shows the aging of unfulfilled sales orders by different time intervals such as 0-30 days, 31-60 days, 61-90 days, and beyond.

By monitoring and analyzing the aging of unfulfilled sales orders, businesses can address delays and take corrective actions. There are numerous benefits:

- It provides insights into the demand for products and helps businesses allocate resources and inventory appropriately.

- It makes sure that customers receive their orders on time.

- In the case of delays, proactive communication can even help manage customer expectations. It does not just mitigate the risk of order cancellations or dissatisfied customers. Timely intervention can also prevent potential issues and preserve the reputation of the business.

- It helps businesses identify bottlenecks in the order fulfillment process and streamline operations to improve overall efficiency.

- A growing backlog may indicate challenges in meeting customer demand, and businesses can use this information to adjust production/ procurement or distribution strategies.

Other Key Performance Indicators (KPIs) to keep an eye on to improve your Order Fulfillment Process

In addition to Order Fulfillment Rate and Aging Orders, there are several other key performance indicators (KPIs) and indexes that can be used to evaluate the efficiency and effectiveness of your order fulfillment process:

Order Accuracy Rate: This measures the percentage of orders that are shipped accurately and without errors. It reflects the precision of your order picking and packing processes.

Order Cycle Time: This index represents the time it takes from the moment an order is placed to the moment it is delivered to the customer. Shorter cycle times indicate a more efficient process.

On-time Delivery Rate: This measures the percentage of orders delivered to customers on or before the promised delivery date. Timely deliveries contribute to customer satisfaction and loyalty.

Perfect Order Rate: This index considers various elements, such as on-time delivery, accurate invoicing, and complete and damage-free shipments. It provides a holistic view of order fulfillment quality.

Order Processing Cost: The cost involved in processing each order, including picking, packing, and shipping. Lowering these costs without compromising quality indicates an efficient fulfillment process.

Regularly tracking and analyzing these indexes can help businesses identify areas for improvement in their order fulfillment processes. Apart from lowering costs, it will ensure customers receive their products accurately and promptly, ultimately leading to increased customer satisfaction and brand loyalty.

#3 Improving your order fulfillment process

Somehow if your current order fulfillment process is barely or not up to standard, you should start examining and exploring different alternative methods to improve it.

You can begin by identifying the factors contributing to your subpar order fulfillment rate. Is it due to the high volume of sales orders? Are staffing levels inadequate? Are they well-trained and knowledgeable in the process? Or could it be attributed to an unorganized warehouse layout? Once you have pinpointed the root cause, there are a few practical steps you may take:

- Automate the routine tasks of order processing. It reduces the risk of errors and speeds up the processing time.Implement a inventory management/ order fulfillment system that provides real-time visibility into stock levels and open orders.

- Utilize Technology for Accuracy by integrating barcode scanning or RFID technology into order picking and packing.

- Optimize Warehouse Layout by reorganizing it for efficiency, placing popular and frequently picked items in easily accessible locations.

- Streamline the order picking process and minimize unnecessary movements by storing products in a logical sequence.

- Integrate order tracking systems with your website and customer service platforms for seamless updates.

- Invest in training programs to ensure that warehouse staff is well-equipped to handle their roles efficiently. Foster a culture of continuous improvement, encouraging employees to provide feedback and suggest process enhancements.

- Establish and regularly review KPIs to measure the efficiency of your order fulfillment process. Monitor metrics such as order accuracy, order cycle time, and on-time delivery to identify areas for improvement.

- Periodically review your order fulfillment processes to identify bottlenecks and areas for improvement. Stay informed about industry best practices and emerging technologies that can further optimize your processes.

Reaching out to an industry leader

As we have seen, improving your order fulfillment process is crucial for enhancing customer satisfaction, streamlining warehouse operations, and at the end driving success for your online store. If you still find it difficult in optimizing your order fulfillment process, why not consider seeking free consultancy from us.

Wavyos Technologies provides a team of seasoned experts who has years of valuable experience in creating the best online stores, Google Rankings (SEO) and warehouse/ logistics best practices. Over the years we have developed our own WooCommerce compatible order fulfillment system to help our clients to carry out their pick, pack, ship more efficiently.

For a demo or more information about how Wavyos Technologies can take your online store and order fulfillment process to the next level, contact us today.

Email: [email protected]

WhatsApp: +852 6099 4407

Related Posts:

- How To Drive Online Sales with Great Product Showcase?

- Custom Website Design and Development

- How to do SEO for WooCommerce?

- More than just WordPress Maintenance

- Selling Your WooCommerce Products on TikTok is Never Easier

- Why should you choose WooCommerce over Shopify?

- What must be considered when choosing a WordPress theme?